|

Sickler Industries began operations in 1984 and over the

course of three decades has expanded to become a full

service sawmill with complete wood processing

capabilities. From bark to boards, our professional

sawyers and craftsmen routinely provide custom log

sawing, kiln drying, moulding, end-matching and more.

Please browse our services and

contact us with any questions you may have.

Custom Sawing

Sickler Industries uses a Wood-Mizer Super Hydraulic

sawmill with a thin kerf band saw for maximum yield and

minimal waste. Our professional sawyers can cut logs up

to 32” diameter and 12’ in length. In addition, we also

process logs for unique live edge slabs in a variety of

different wood species.

Sickler’s custom sawing services is extended to

customers who have their own logs and can transport them

to the mill for sawing. Our staff will determine the

amount of lumber that can be expected with your required

dimensions. Looking for curly, spalted, birdseye or

other wood with distinctive characteristics? We often

process logs with these unmistakable patterns and make

them available for sale.

Contact Sickler

with your custom sawing needs.

Kiln drying is an important part of our sawmill

operations. Properly dried wood reduces weight, controls

shrinkage, machines and finishes better and ultimately

reduces the risk of staining, decay and mold. After kiln

drying, we closely monitor the dried lumber using a

moisture meter to spot check each batch.

Our

dehumidification kiln reduces moisture content to 6-8%

and some wood species can be dried to have a lower

percentage. The kiln is continuously in operation 24/7

around the clock and can hold up to 5,000 board feet at

one time. Drying time can vary (up to 3 weeks) depending

on the thickness of the lumber/slabs and also the

species of wood. All lumber and slabs to be dried are

stored inside of our warehouse and out of inclement

weather.

Sickler Industries has made its kiln

available to customers that have their own logs to be

sawn and dried. Contact us for

an estimate and to schedule drying time.

Nearly every piece of rough-cut lumber passes through

our straight line rip saw in preparation for production.

Straight line ripping creates a square, even edge on the

lumber. We use a Cantek® ripsaw that has absolute

straight line feeding in a small footprint and creates a

perfectly straight cut (glue line) free of saw marks. An

integrated laser line improves accuracy, provides fast

lumber positioning and reduces material waste.

The centerpiece and workhorse of the millwork shop is

our Weinig® pass-through moulder. This multi-axis

cutting machine creates profiled mouldings from square

stock with exceptional accuracy and speed. From complex

crown and baseboard moldings to tongue & groove edging

and intricate chair rail pieces, Sickler can make

virtually any profile.

Each workpiece passed through the moulder has

exceptional surface quality. Our moulder can plane and

profile wood up to 8” wide. Large handrails and wide

baseboard profiles are machined as easily as the

smallest trim.

Contact Sickler

about custom matching your unique wood molding.

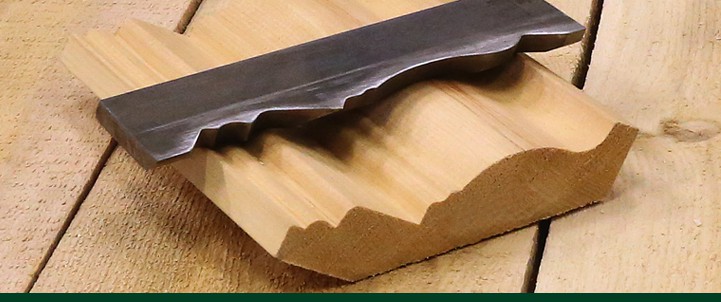

All profiles that are cut from wood on our moulder

require a cutting knife. These high-strength steel

knives spin at high speeds to mould a distinct profile

from square stock. The design options for custom knife

profiles are endless.

Sickler Industries has over 200 knife profiles for

manufacturing a wide variety of mouldings. Casing,

baseboard, chair rails and other moulding styles all

require a different knife to create them. All of our

cutting knives are made in-house to save you time and to

ensure proper cutting with our equipment.

Click here

to learn more about our cutting knives and available

sizes.

End-matching is the process of machining a tongue on one

end of a board and a groove on the other. Our Doucet®

End Pro End-Matcher specifically cuts this end profile

on our paneling and flooring products. The end-matcher

can cut material up to 6” wide and as short as 16” long.

Click here

to learn more about end-matching our paneling and

flooring.

No millwork shop would be complete without an industrial

planer. We use a Baker® surface planer for smoothing and

flattening live edge slabs and to accurately plane other

material to specific thicknesses.

The surface

planer has a 23-1/2” width capacity and uses a rugged

helical cutter head to remove material. The planer has a

minimum planing thickness of 1/8” and maximum thickness

of 7”.

Our Timesavers® Speed Sander says it all. It saves time

by mitigating the amount of hand labor on sanding and

allows workpieces to rapidly progress through

production.

The Speed Sander uses a combination drum and platen head

to quickly improve the finish on wood. Live edge slabs,

combined panels and other large glue assemblies are

sanded to perfection in minutes.

The sander has a maximum 36” working width and a digital

thickness guage for adjusting the bed opening (up to 6”

high). A variable speed conveyor provides in-feed speeds

of 10-30 FPM.

Sickler’s shop includes a large glue-up clamp rack for

the proper assembly of glued millwork. When wood

assemblies need to be bonded together to create larger

pieces or different wood species are combined to create

a unique look, they are glued and clamped together on

the rack. Some examples include: flat stock panels,

butcher block, handrails, posts and countertops.

The multi-level clamp rack can secure wood assemblies as

large as 36” wide and up to 12’ long.

Sickler Industries sales office, located on US-41 in

Mohawk, Michigan, maintains an inventory of stock

millwork for walk-in purchase. Various mouldings,

paneling and hardwood flooring in select wood species

are typically stocked and available to the public.

Contact Sickler

to reserve or order your custom millwork today.

|