|

Sickler Industries provides a full array of different

mouldings and specialty millwork. With over

200

different molding profiles in stock and a variety of

native (oak, maple, cedar, pine, cherry,

birch,

aspen, poplar) and non-native species (hickory, walnut)

readily available, our millwork

shop is prepared to

work on your next project.

We routinely supply home building contractors, door &

window manufacturers, specialty shops and homeowners

with a wide variety of casing, chair rail, baseboard and

crown mouldings. Other millwork typically consists of

handrails and stair parts, rosettes, plinth blocks,

corner and panel trim, quarter round and picture

mouldings.

We encourage you to browse the moulding and millwork

gallery below. Our selection includes styles ranging

from 1/2” up to 6-1/2” in width. Lengths commonly range

from 2’ to 8’ with select species available up to 12’.

Not all profiles are shown.

Contact Sickler for

specific moulding styles not shown or custom-matching

your moulding.

| |

|

|

|

|

|

|

|

|

|

COLONIAL CASING

11/16 in. x 2-1/2

in.

Part # CB2506802

| |

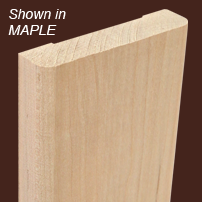

RANCH CASING

3/4 in. x 2-1/2 in.

Part # CB2507514

|

|

COLONIAL CASING

3/4 in. x 2-3/4 in.

Part # CB2757504

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

FLAT CASING

7/16 in. x 3-1/4

in.

Part # MC-34

| |

COLONIAL CASING

3/4 in. x 3-1/4 in.

Part # MC-70

|

|

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

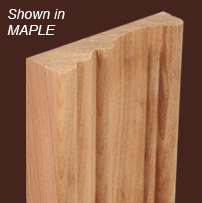

FLUTED CASING

3/4 in. x 3-1/4 in.

Part # FD32504

| |

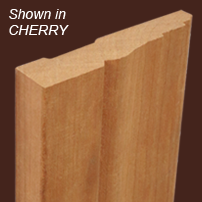

FLUTED CASING

5/8 in. x 2-15/16

in.

Part # 39103

|

|

FLUTED CASING

5/8 in. x 4 in.

Part # SIK12191

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

CHAIR RAIL

3/4 in. x 2-5/16

in.

Part # 3103

| |

CHAIR RAIL

7/8 in. x 2-3/8 in.

Part # 1113095

|

|

CHAIR RAIL

3/4 in. x 2-1/4 in.

Part # 12202

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

CHAIR RAIL

3/4 in. x 6-1/4 in.

Part # 31051

| |

FLUTED CHAIR RAIL

5/8 in. x 4 in

Part # SIK12191

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

COLONIAL BASE

3/4 in. x 5-1/2 in.

Part # CB5507501

| |

COLONIAL BASE

3/4 in. x 3-1/2 in.

Part # CB3507503

|

|

COLONIAL BASE

5/8 in. x 3-1/4 in.

Part # CB3256809

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

COLONIAL BASE

3/4 in. x 5-1/2 in

Part # 319081

| |

COLONIAL BASE

3/4 in. x 5-1/2 in

Part # CB4007502

|

|

COLONIAL BASE

5/8 in. x 4-1/4 in.

Part # CB4256203

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

CROWN

11/16 in. x 3-5/8

in.

Part # 3623

| |

CROWN

3/4 in. x 2-1/2 in.

Part # 2501

|

|

CROWN

7/8 in. x 4-5/16

in.

Part # 11105

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

CROWN

3/4 in. x 5-1/4 in.

Part # 52592

| |

CROWN

13/16 in. x 2-1/2

in.

Part # 814061

|

|

CROWN

13/16 in. x 2-13/32

in.

Part # SIK10830

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

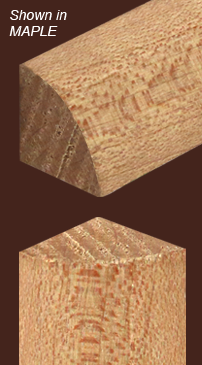

HANDRAIL

2-5/8 in. x 2-5/8

in.

Part # HRP262601

| |

HANDRAIL

3 in. Diameter

Part # 1201051

|

|

CHAIR RAIL

1.5 in. Diameter

Part # F1-50

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

HANDRAIL

1-5/8 in. x 5-1/2

in.

Part # 162-250

| |

HANDRAIL

2 in. x 2 in.

Part # H162-250

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

COVE/INSIDE CORNER

1/2 in. x 1/2 in.

Part # 1/2" COVE

| |

COVE/INSIDE CORNER

3/4 in. x 3/4 in.

Part # 3/4" COVE

|

|

PANEL MOULDING

5/8 in. x 3/4 in.

Part # PABC75620

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

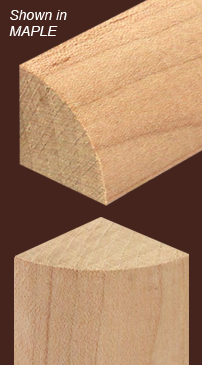

QUARTER ROUND

1/2 in. x 1/2 in.

Part # 1/2" QR

| |

QUARTER ROUND

3/4 in. x 3/4 in.

Part # 3/4" QR

|

|

QUARTER ROUND

15/16 in. x 15/16

in.

Part # 15/16" QR

|

|

| |

| |

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

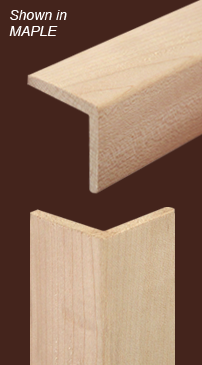

OUTSIDE CORNER

1-1/2 in. x 1-1/2

in.

Part # 209071

| |

TRANSITION STRIP

23/32 in. x 2 in.

Part # 32032

|

|

COLONIAL STOP

1/2 in. x 1-3/4 in.

Part # 4103

|

|

| |

| |

|

|

| |

| |

|

| |

|

|

|

|

|

|

|

|

|

PANEL MOULDING

5/8 in. x 1-1/4 in.

Part # 12201012

| |

PANEL CAP

1-1/2 in. x 1-13/16

in.

Part # 61542

|

|

PICTURE MOULDING

1 in. x 2-1/2 in.

Part # PACM25100

|

|

| |

| |

|

|

PICTURE MOULDING

1-1/8 in. x 2-7/8

in.

Part # 1214072

|

|

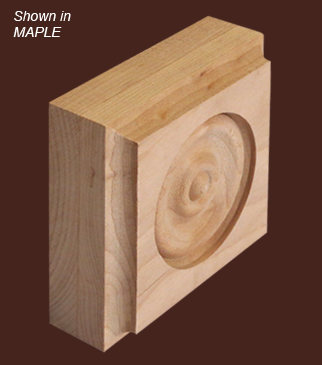

2-1/8" DIA. ROSETTE

1-1/8 in. x 3-1/4

in.

Part # N/A

|

|

|

|

|

|

|

|

|

|

PLINTH BLOCK

1-1/16 in. x 3-3/4

in.

Part # N/A

|

|

PLINTH BLOCK

1-1/8 in. x 3-1/4

in.

Part # N/A

|

|

|

|

|

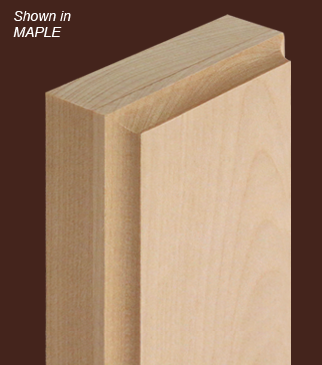

Historically Accurate Pine Baseboard

Sickler Industries was approached by the Keweenaw

National Historical Park to recreate a historically

accurate baseboard molding for the Park’s Visitor Center

in Calumet, Michigan.

Our craftsmen were able to develop an accurate template

from an existing wood sample and create a new profile

knife blade using our in-house precision tool grinder.

With the blade developed, our millwork shop prepared

multiple sample pieces for review and final approval by

Park officials. Today, the painted pine baseboard can be

found throughout the K.N.H.P. Calumet Visitor Center in

various exhibit rooms.

Contact Sickler

about recreating your historical moulding.

In-House Profile Cutting Knives

For the fastest turnaround and precision fit with our

moulder equipment, Sickler’s millwork staff can create a

new cutting knife to match your existing moulding

profile or grind an entirely new blade for your project.

Each profile cutting knive is made in-house to save you

time and to ensure a proper cut.

Sickler Industries manufactures all cutting knives from

premium high-speed knife steel. This blade material

provides an exceptional cutting edge and can be reground

for sharpening without any loss in cutting tolerance.

Blade sizes can range from 1/2” up to 6-1/2” wide.

Sickler Industries has specialized in sawing dimensional

lumber for over three decades. Whether you look to have

timber from your property dimensionally cut or your

business requires lumber cut to an exact spec (actual

size), our sawyers and millwork craftsmen can provide

you Rough Cut or S4S lumber in either knotty or select

grades.

Rough-Cut Lumber

Rough-cut or rough-sawn lumber is cut directly from the

log into planks and does not contain any pre-surfaced

(planed) sides. Rough-cut wood is either air dried or

kiln dried. Rough-cut lumber will contain more moisture,

but is the best selection if you require thick boards

for your building project.

Surfaced Four Sides (S4S)

Lumber that has been surfaced on both faces (S2S) and

ripped on both edges. S4S is kiln dried with flat and

parallel faces and edges. This is the most common type

of surfaced lumber available due to the uniformity of

all dimensions.

Contact Sickler

for more information about cutting your dimensional

lumber.

Sickler Industries quality butcher block is assembled

using premium hardwood strips of durable maple, birch

and oak. The edge grain strips are bonded together using

food safe glue, then planed and sanded for final

finishing. End grain (checkerboard) butcher block is

also available upon request. Sickler Industries quality butcher block is assembled

using premium hardwood strips of durable maple, birch

and oak. The edge grain strips are bonded together using

food safe glue, then planed and sanded for final

finishing. End grain (checkerboard) butcher block is

also available upon request.

Butcher block is an economical alternative to marble or

quartz surfaces and is commonly used for countertops,

stair treads, kitchen islands, tabletops, cutting boards

and decorative inlays.

|